High performance DIA & CBN double disc grinding wheels for face and finegrinding

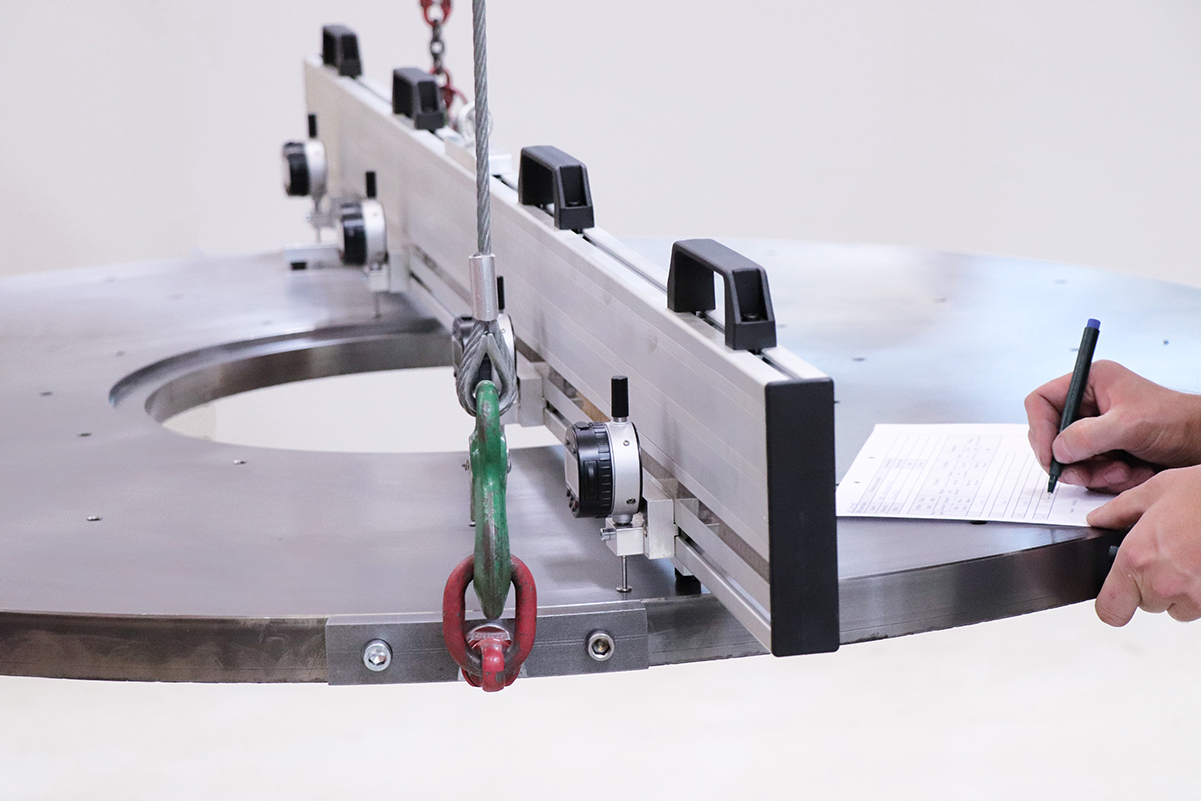

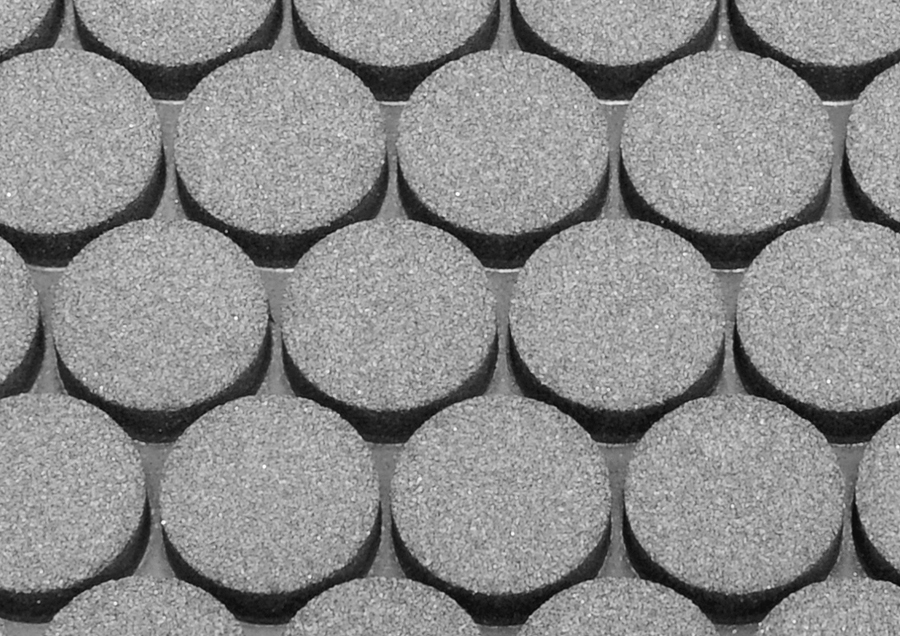

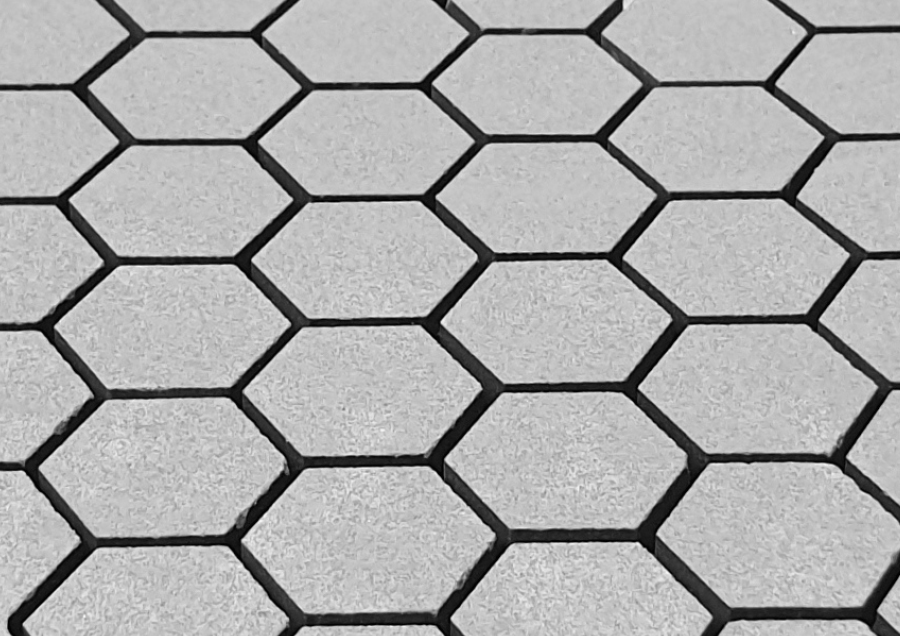

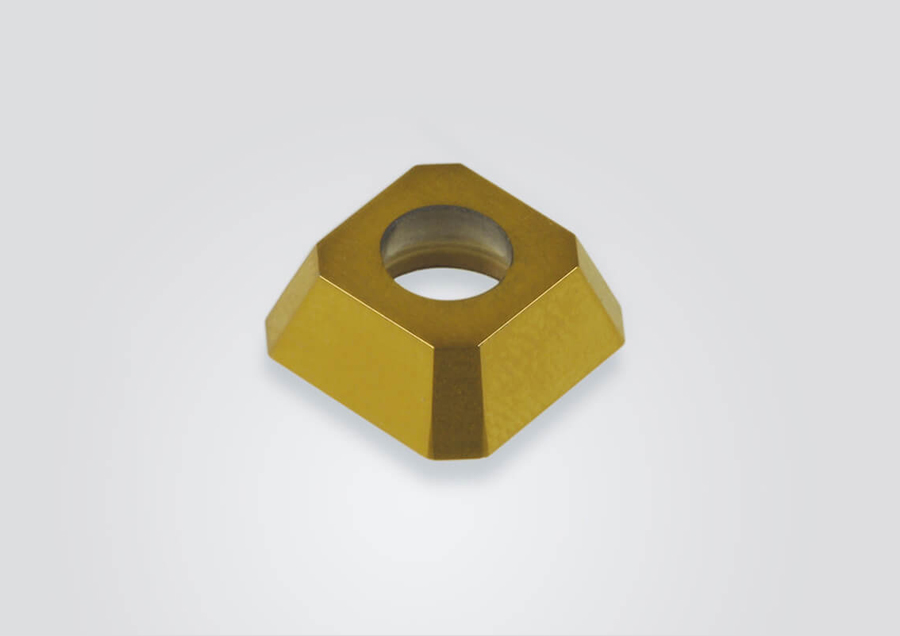

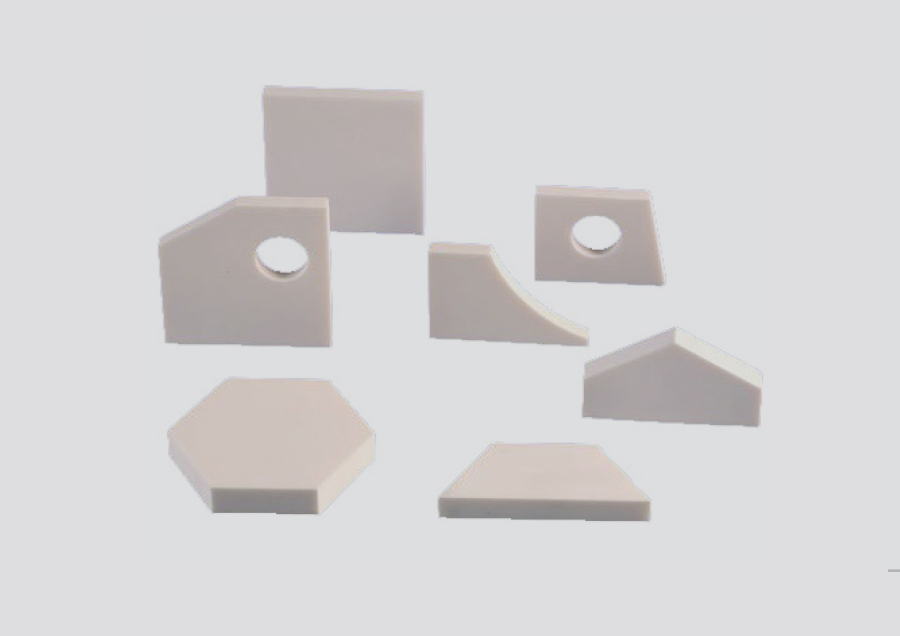

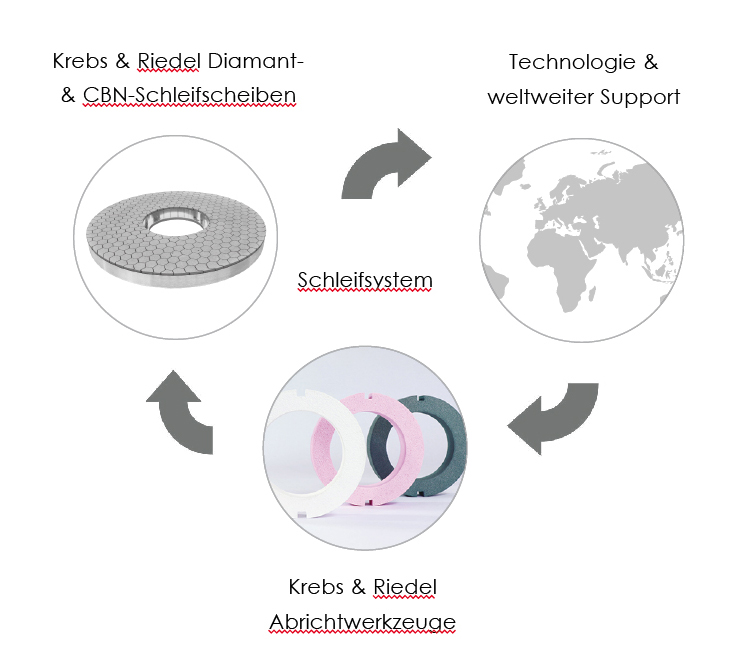

High performance DIA & CBN double disc grinding wheels for face and finegrinding Krebs & Riedel has many years of experience and references in double disc grinding. We offer tailor-made solutions for a wide range of applications, machines and workpieces in the area of face and finegrinding. Krebs & Riedel manufactures double disc grinding wheels up to 1500 mm outer diameter made of DIA and CBN in vitrified bond for the effective creation of flat surfaces with a high surface quality and shape tolerance for a wide range of different materials. The range includes grinding tools in different segmentation for single and double disc grinding machines with and without planetary kinematics. Compared to other systems, the vitrified bond system by Krebs & Riedel allows the production of very free cutting and porous coating structures. This results in a significant increase in productivity.

Our ceramic bonding system allows the production of very sharp and porous coating structures. This allows a significant increase in productivity, as well as the finest surfaces for metal, ceramics and plastics.

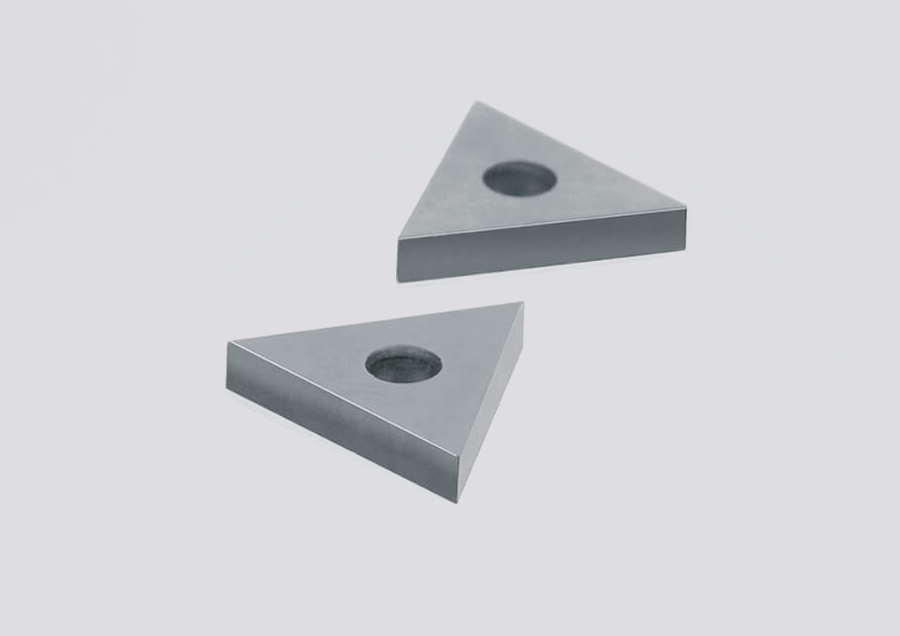

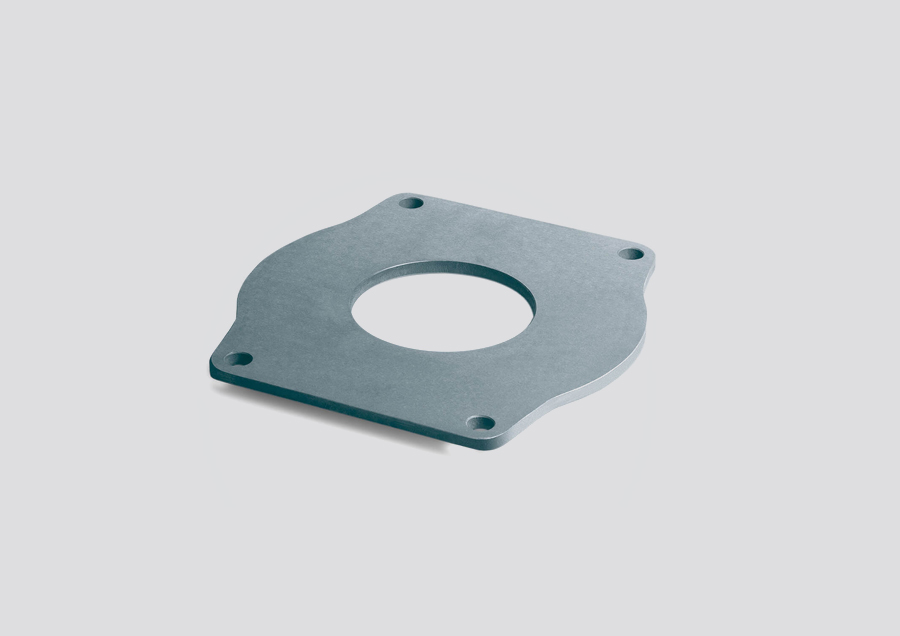

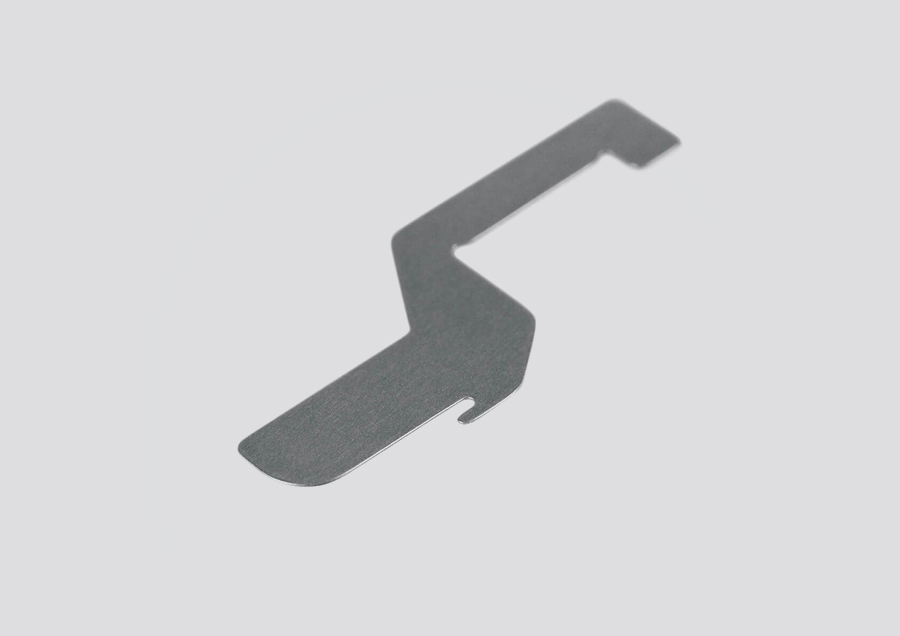

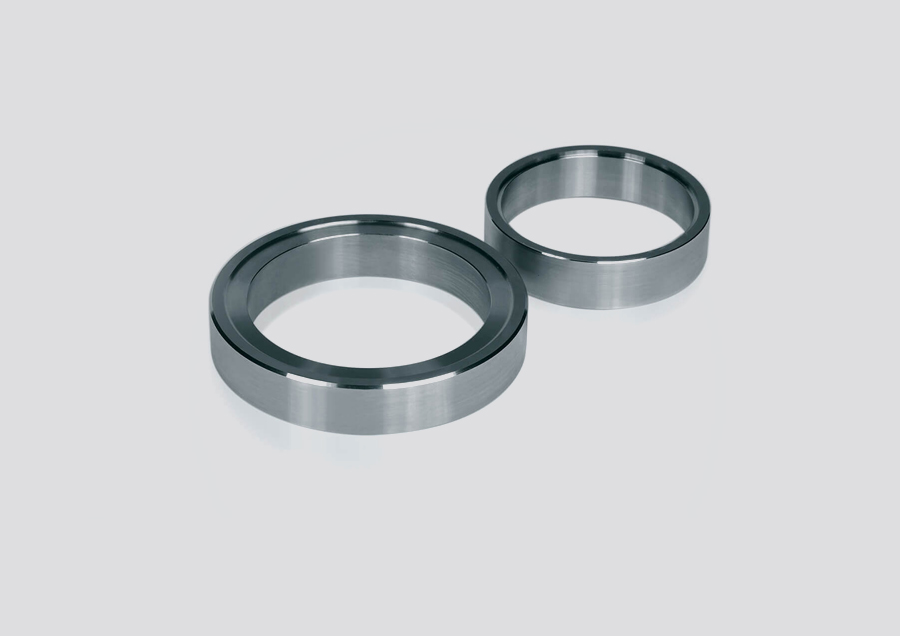

Our bonding systems are extremely effective in machining a wide variety of ceramics, cast materials, sintered metals, hardened steels and hard metal products. E.g. sealing discs, valve plates, pump rings and housings, roller bearing rings, knives and carbide cutting tools. High stock removal rates and tool life for rolling bearing steel such as 100Cr6 characterize our specifications. In addition to an intensive process analysis, we supply you with double disc grinding wheels and sharpening rings that are adapted to your production processes and tailored to your requirements.

Your advantages

- Many years of experience and strong references

- Bespoke solutions with quality tools

- Pellet dimensions possible from 12 to 30mm

- Solutions for roughing applications with high stock removal rates

- Pre- and finish-grinding with one machine concept

- Customer service and application support worldwide

- Fast delivery times and flexibility

- All products are „Made in Germany“

- Highest precision and excellent tool life

- Finest workpiece surface qualities

- Disc diameters up to 1500 mm

- Continuous development of specifications

Our service

- Selection of the optimal specification

- Pre-tests with own laboratory machine minimizes risk

- Production of customer specific grinding tool type

- Recommendation of the appropriate dressing strategy

- Recommendation for appropriate process parameters

- Recommendation for appropriate cooling lubricants

- Coordination & solution for the specific application

- Dilligent process documentation

- Continuous optimisation

- Application-oriented user training

- Repair of segments / replacement

- Recoating of the double disc grinding wheel base bodies

- Close cooperation double disc machine manufacturers